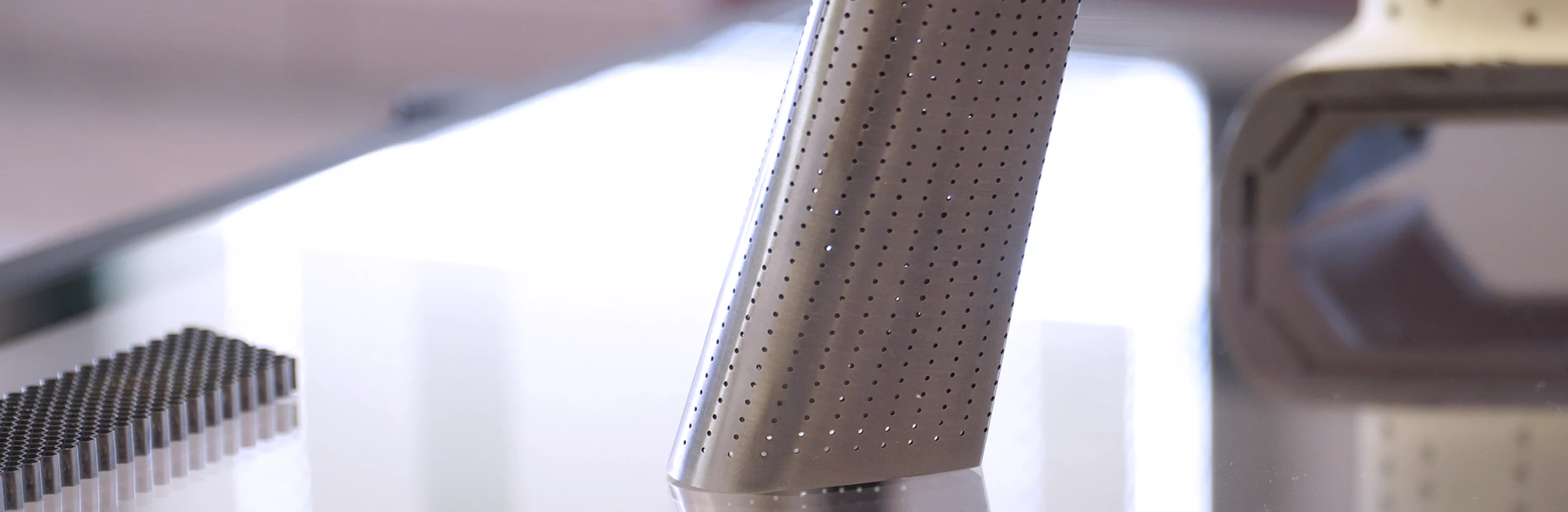

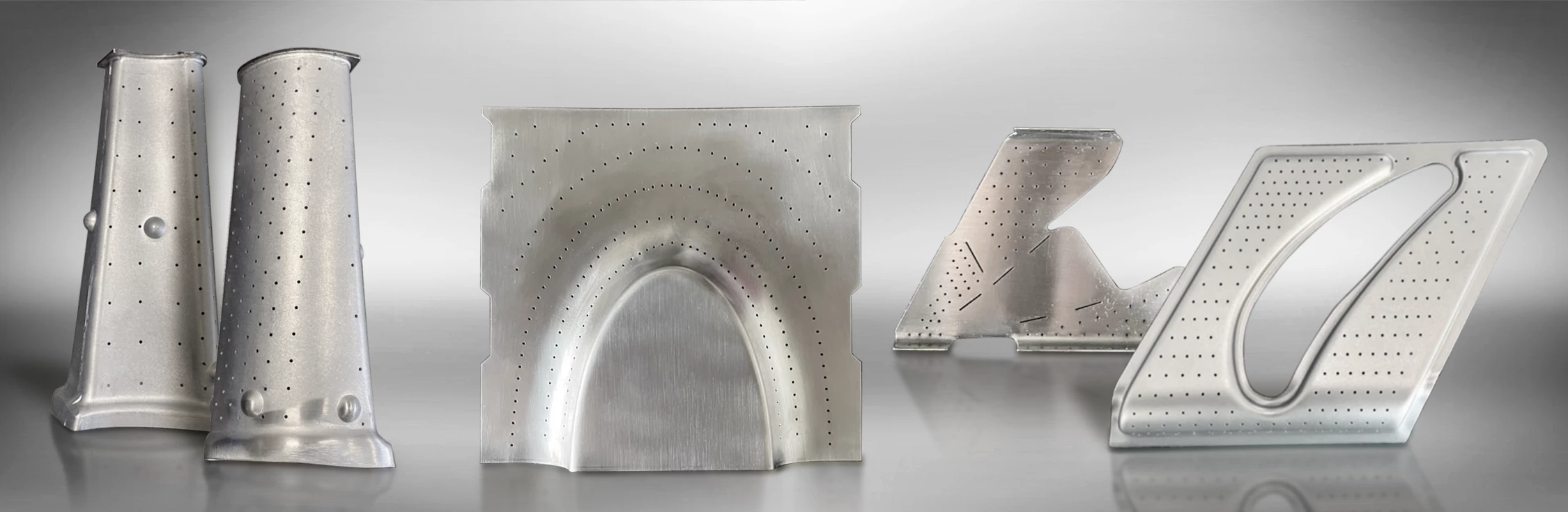

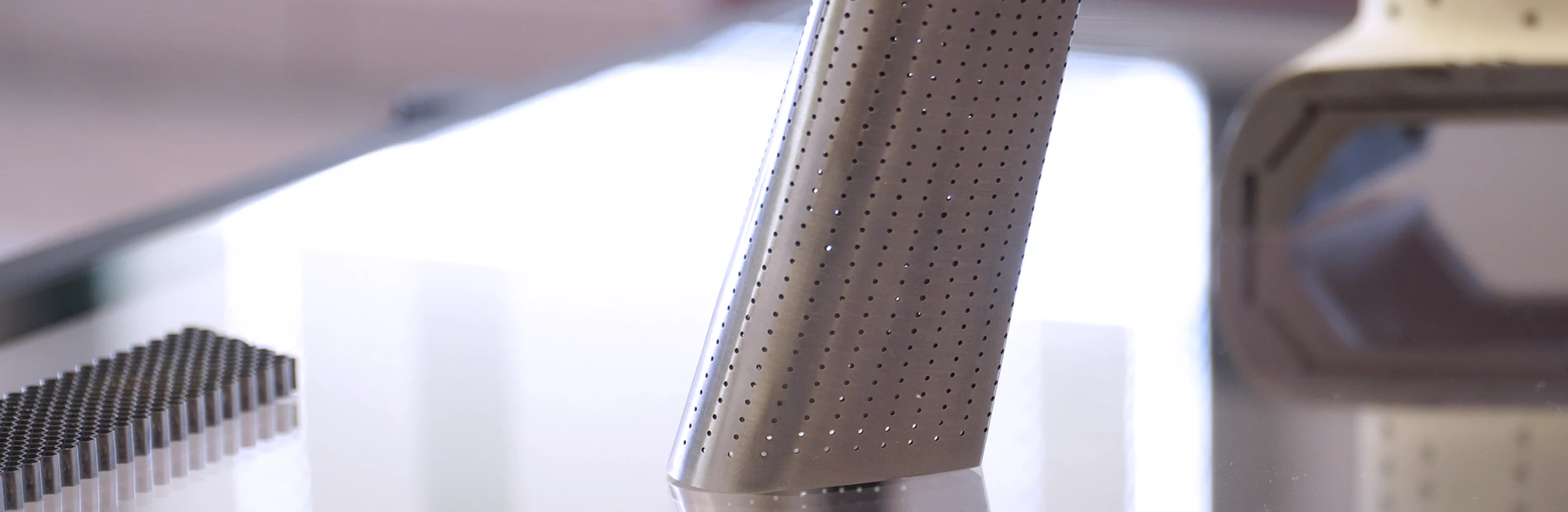

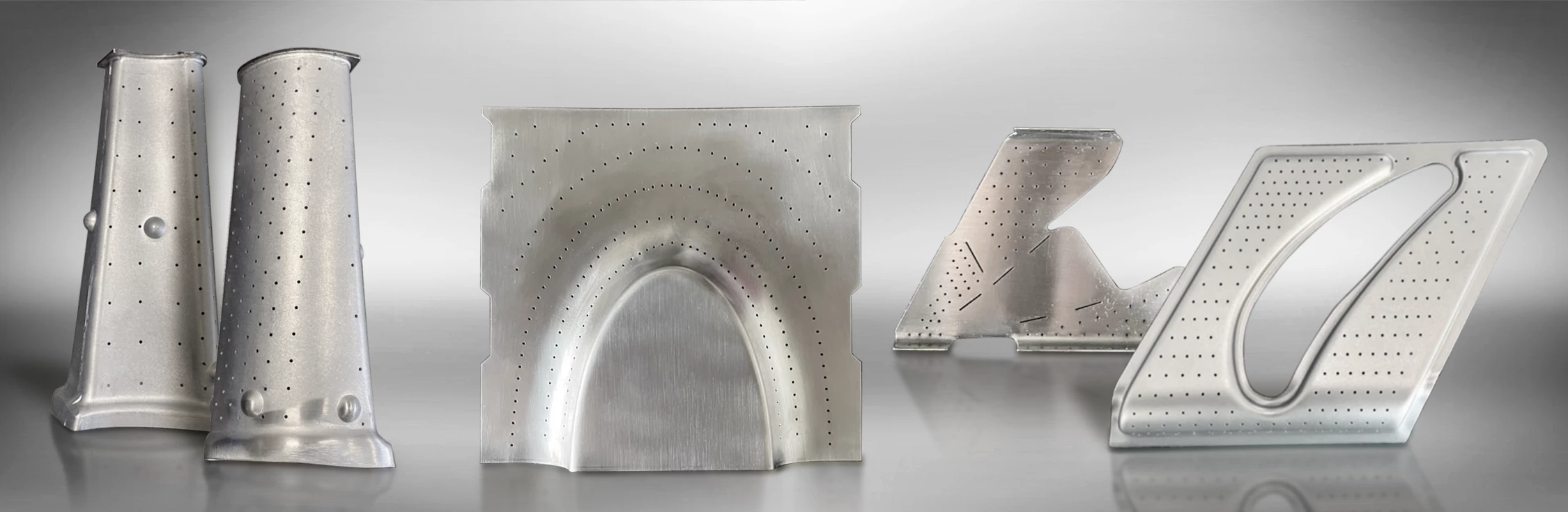

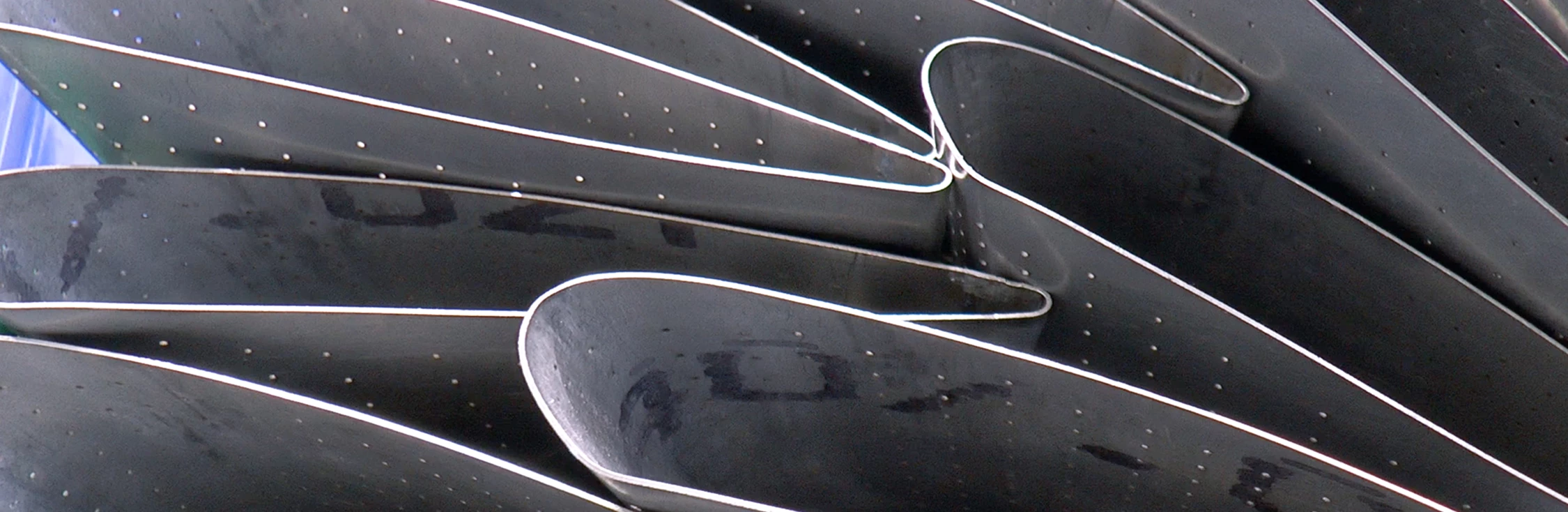

Cooling inserts, essential components in turbines, are designed to improve thermal efficiency and extend the life of turbine components. Using state-of-the-art technology and high-quality materials, at SILMEC Srl we produce inserts that meet the industry's most stringent specifications.

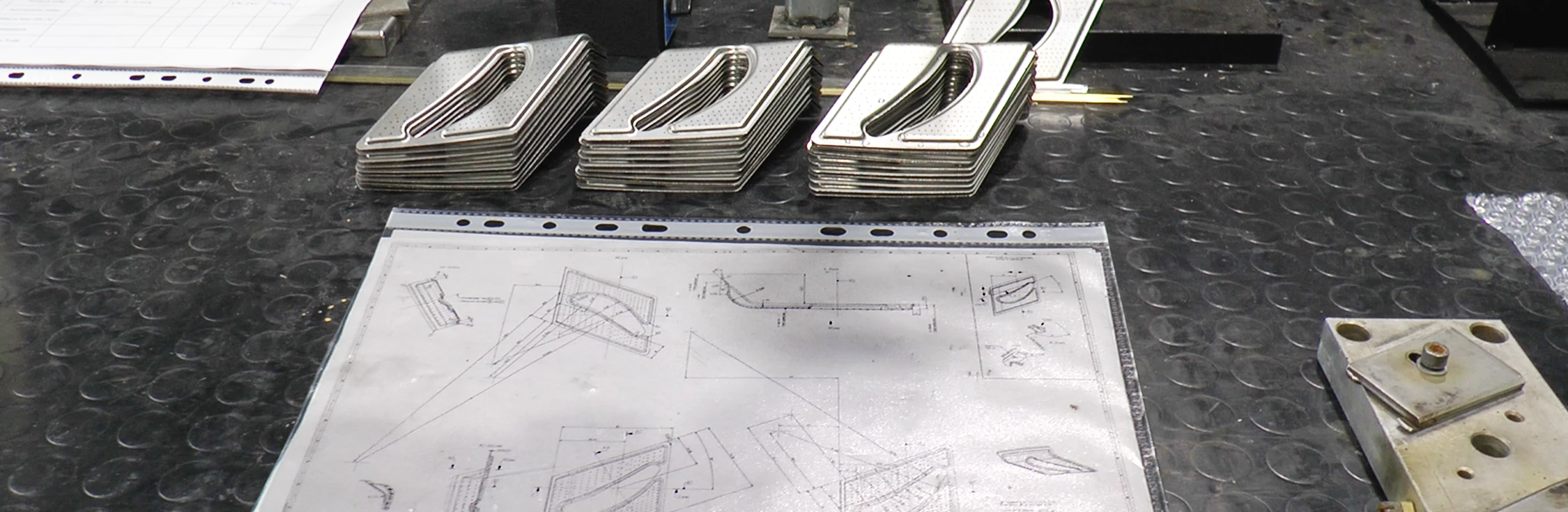

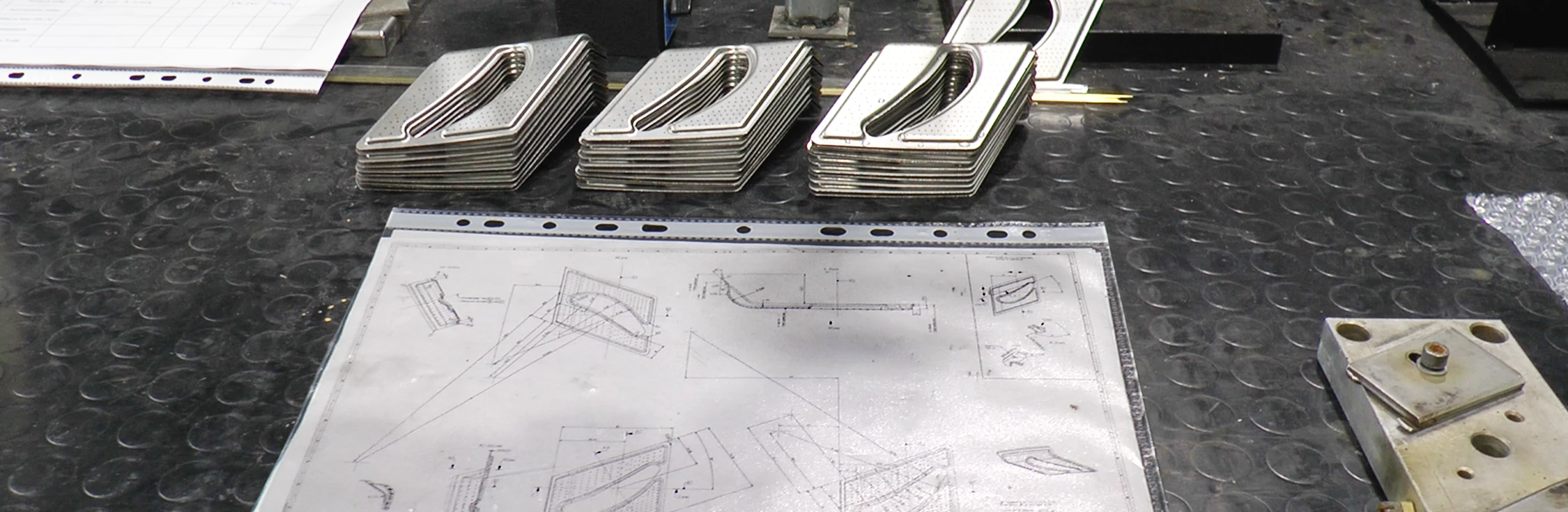

combines the accuracy of EDM technology with the versatility of 5-axis machining.

enables the production of inserts with complex geometries and extremely tight tolerances..

ideal for intricate details and high-quality surfaces..

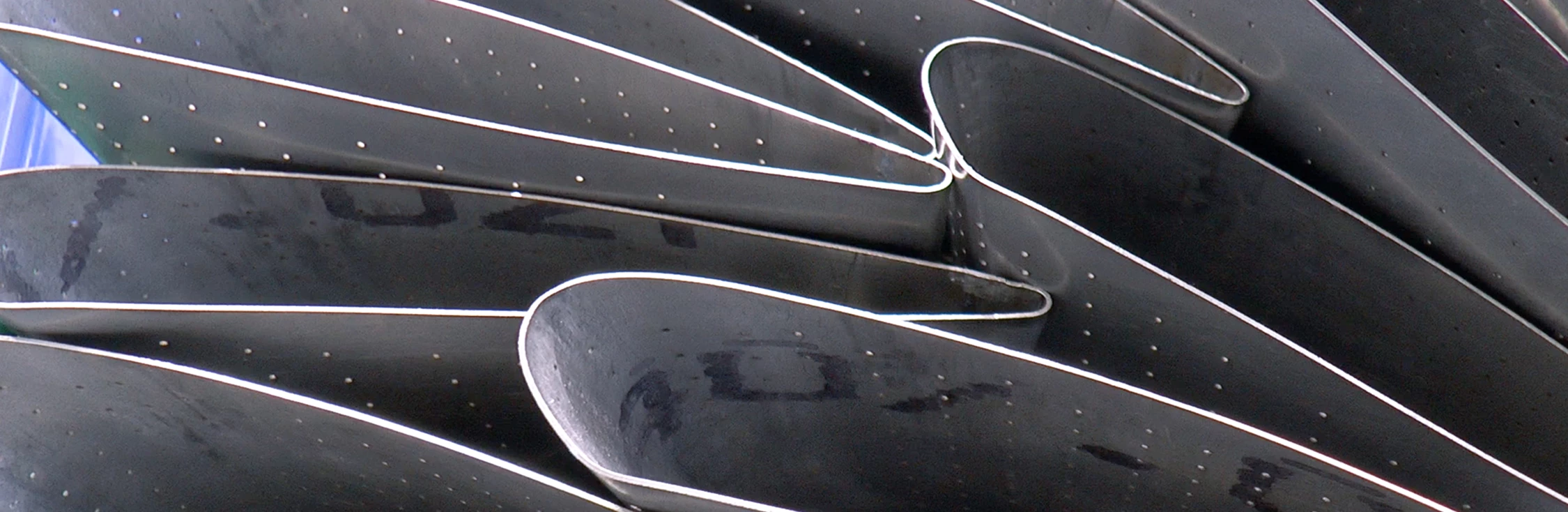

inserts used in gas and steam turbines for power plants..

applications in aircraft engines for greater efficiency and safety.

use in turbines for ships and high-speed trains.

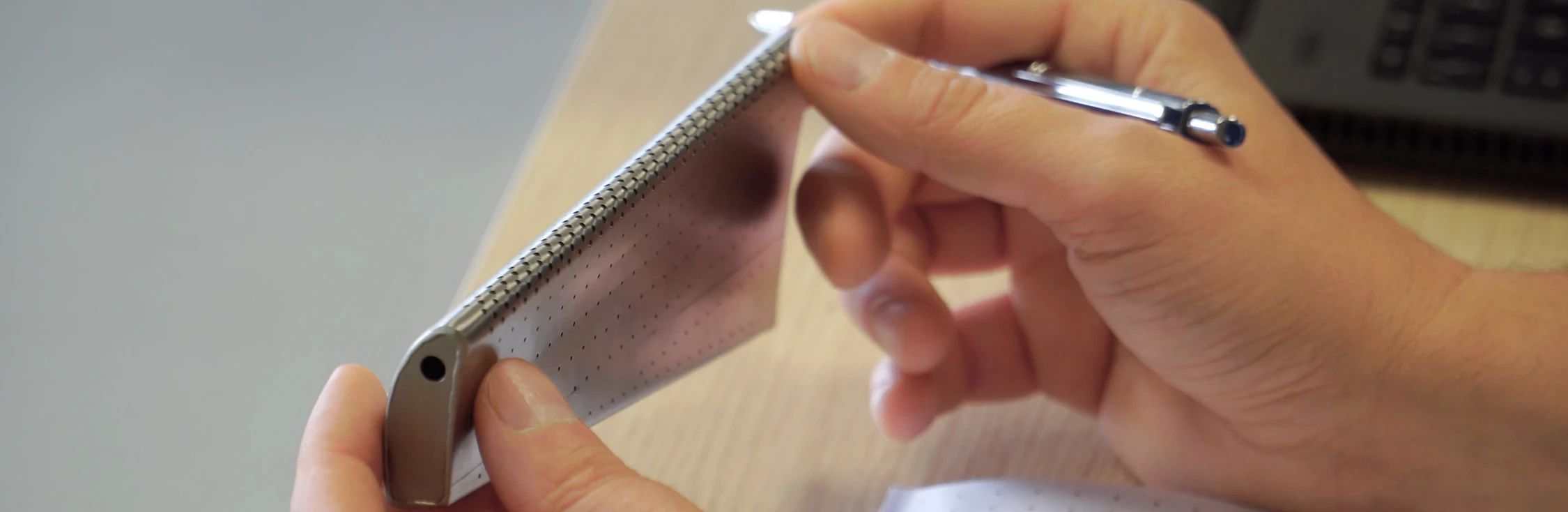

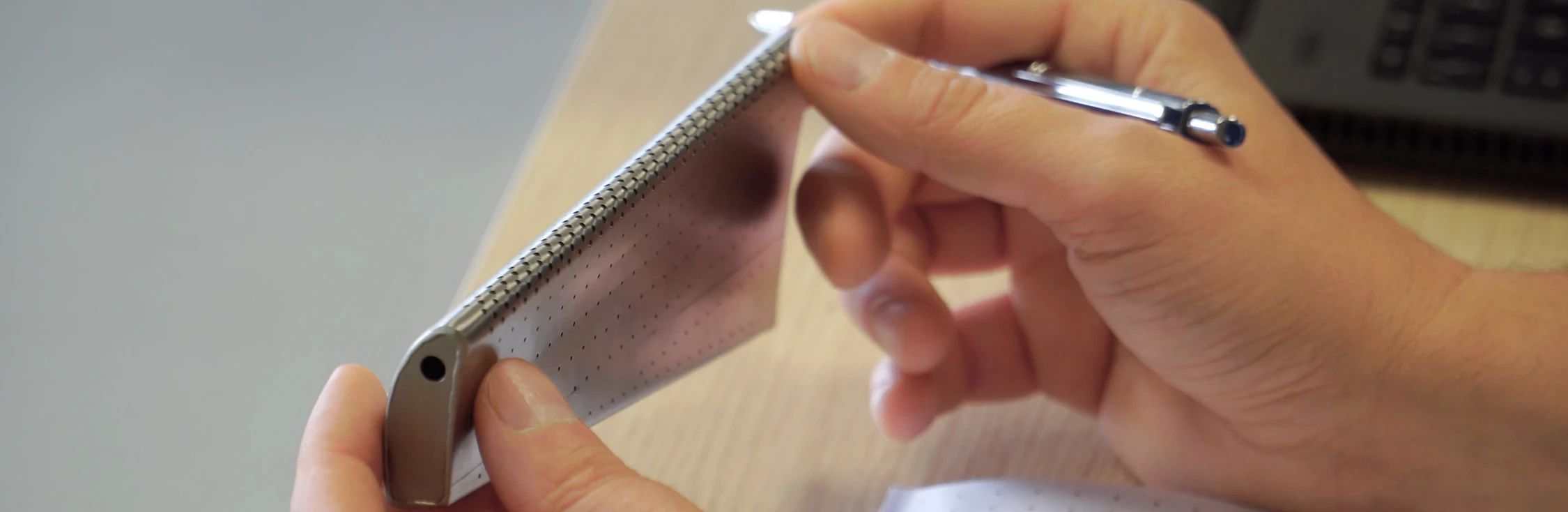

rigorous quality control and compliance with international standards.

constant investment in research and development to improve our processes and products.

dedicated technical assistance to optimise the integration of our inserts into customer systems.

implementation of cooling inserts for one of the largest power plants in Europe, improving efficiency by 15%.

constant investment in research and development to improve our processes and products.

supply of inserts for new generation aircraft engines, helping to reduce operating costs and emissions.