Whether it’s about cutting or drilling steel, superalloys, titanium, or aluminum components with surgical precision, choosing a partner like Silmec Srl means relying on expertise, efficiency, and the right equipment.

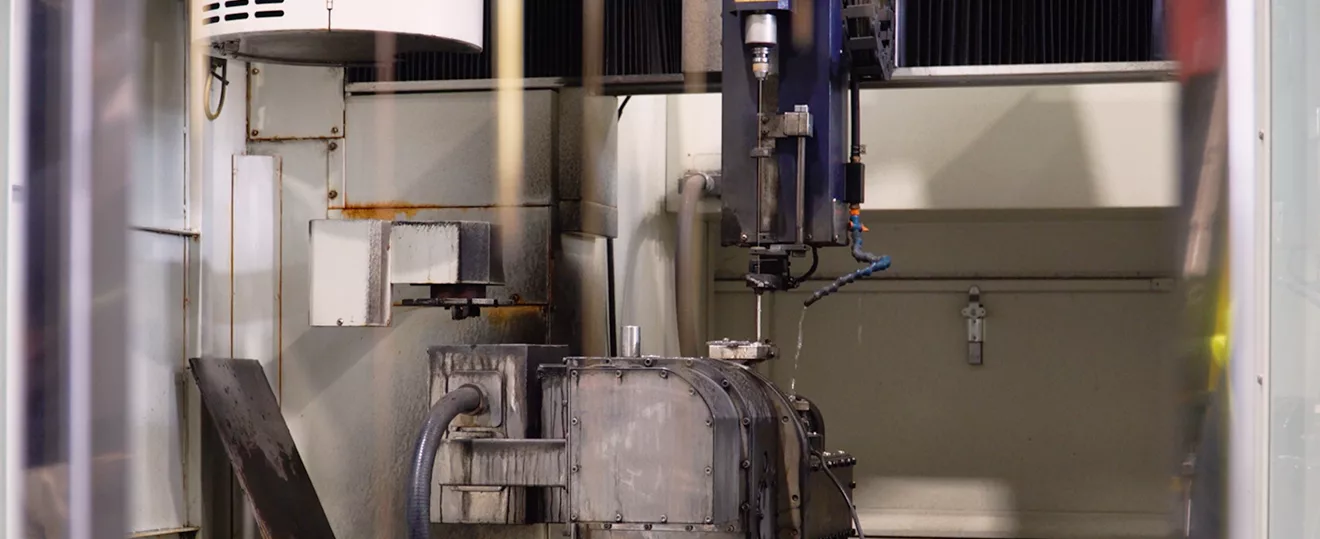

The process is sophisticated. It’s not just about “cutting or drilling metal.” It requires next-generation multi-axis machinery integrated with CNC controls, dedicated software, and skilled operators capable of understanding the materials, programming paths, and managing the process under optimal conditions, all while optimizing production times. At Silmec Srl, this expertise has been available for over 20 years, especially in the production of gas turbine components, which are typically made from nickel- and cobalt-based superalloys or titanium alloys—materials that are very hard and tough, and difficult to machine with traditional chip removal techniques.

Wire EDM is a technology that offers several significant advantages:/p>

Today, manufacturing companies must focus on efficiency and resource optimization. Outsourcing EDM processes to specialized partners like Silmec means gaining access to high-level know-how and cutting-edge technology. At Silmec Srl, companies find a flexible and skilled partner capable of scaling production as needed and managing even significant workload peaks. We continuously invest in training and regularly upgrade our machinery. Our expertise is certified and trusted by customers in strategic industrial sectors (energy, aerospace, transportation, medical, etc.), who rely on us to improve overall efficiency and final product quality.

Wire EDM is suitable for any electrically conductive material. This includes a wide range of metals and alloys, such as:/p>

Essentially, if a material conducts electricity, wire EDM is a valid machining method.

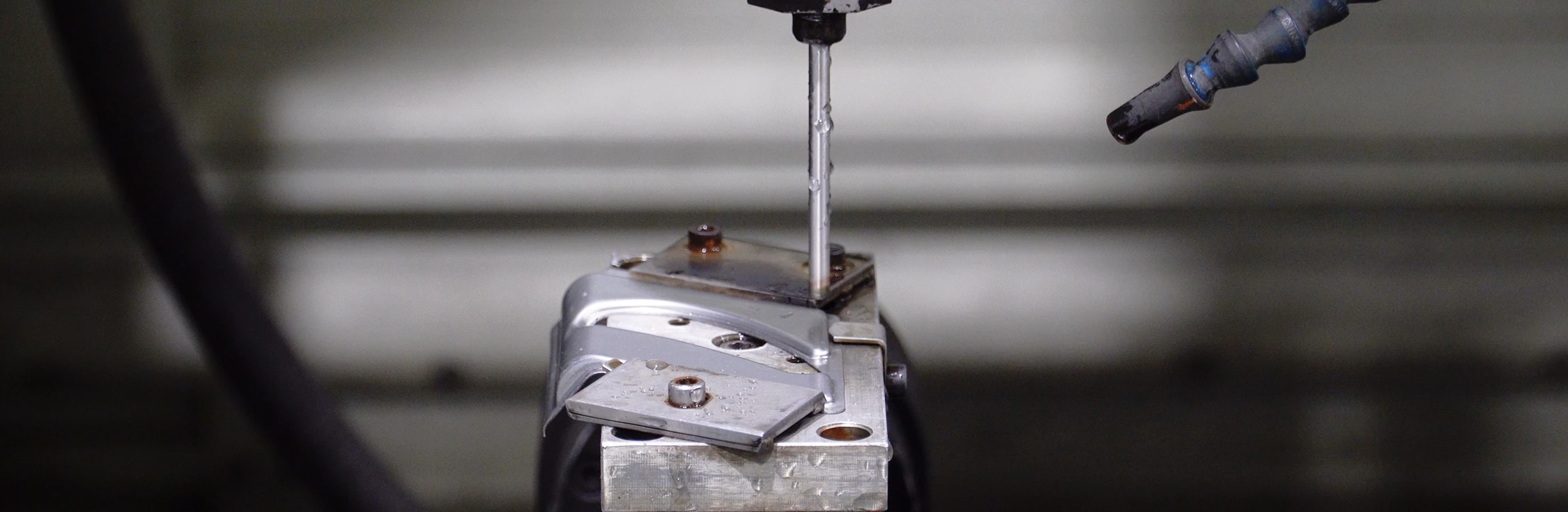

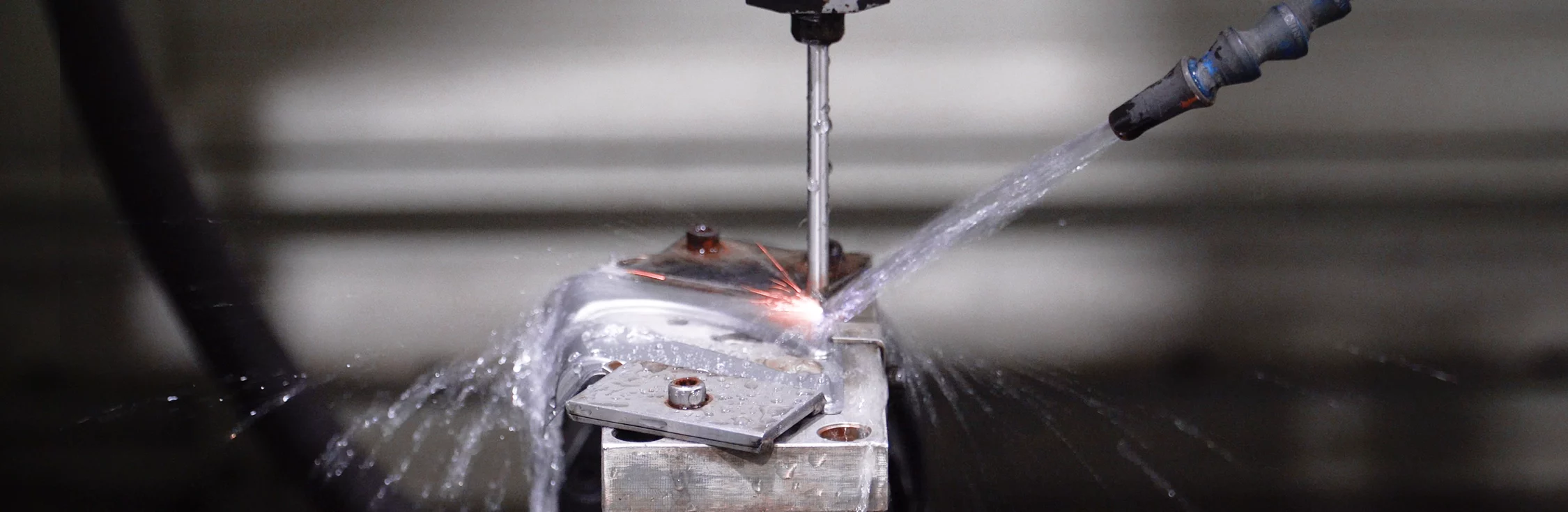

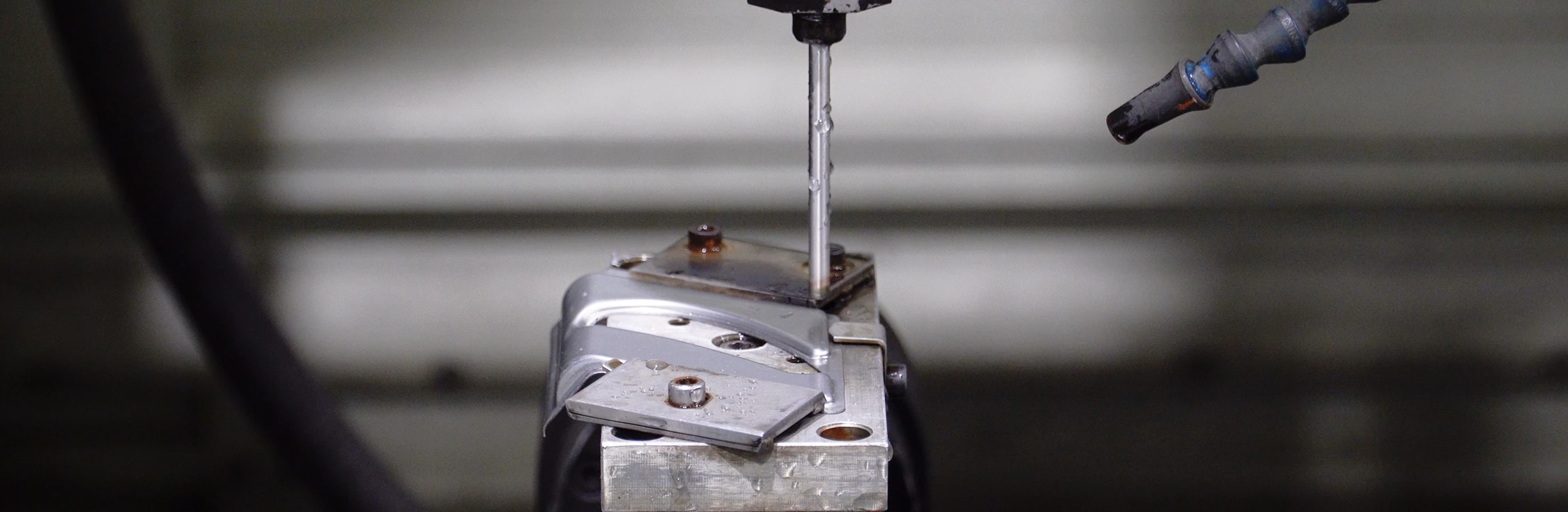

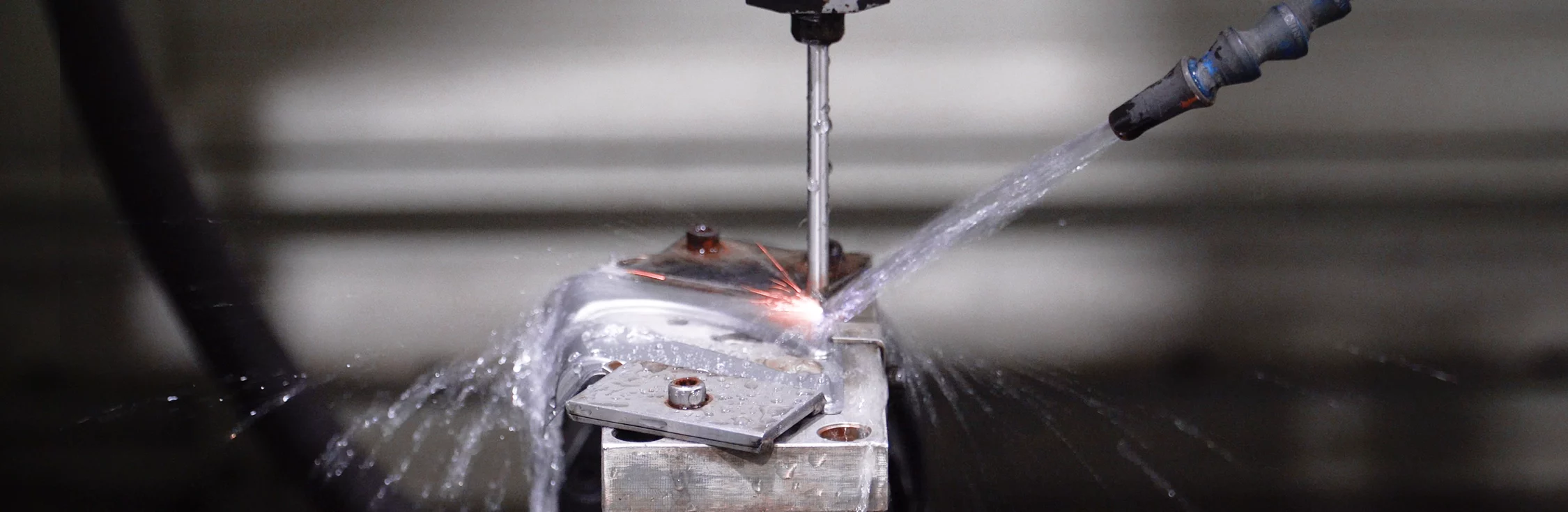

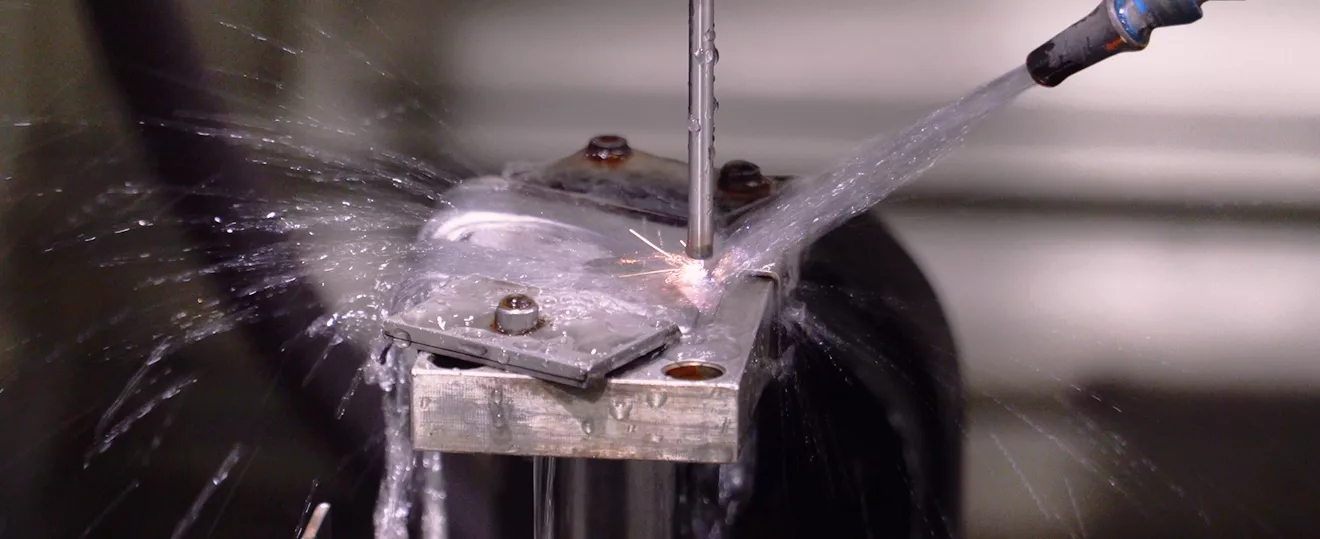

An ultra-thin wire, around 0.30 mm in diameter and made from a conductive material, is electrically charged and guided near the workpiece. There is no physical contact—between the wire and the metal, a powerful, highly focused spark is generated that vaporizes a minuscule portion of the material. The wire follows a pre-programmed path, all while submerged in a dielectric fluid that prevents short circuits and flushes away debris.

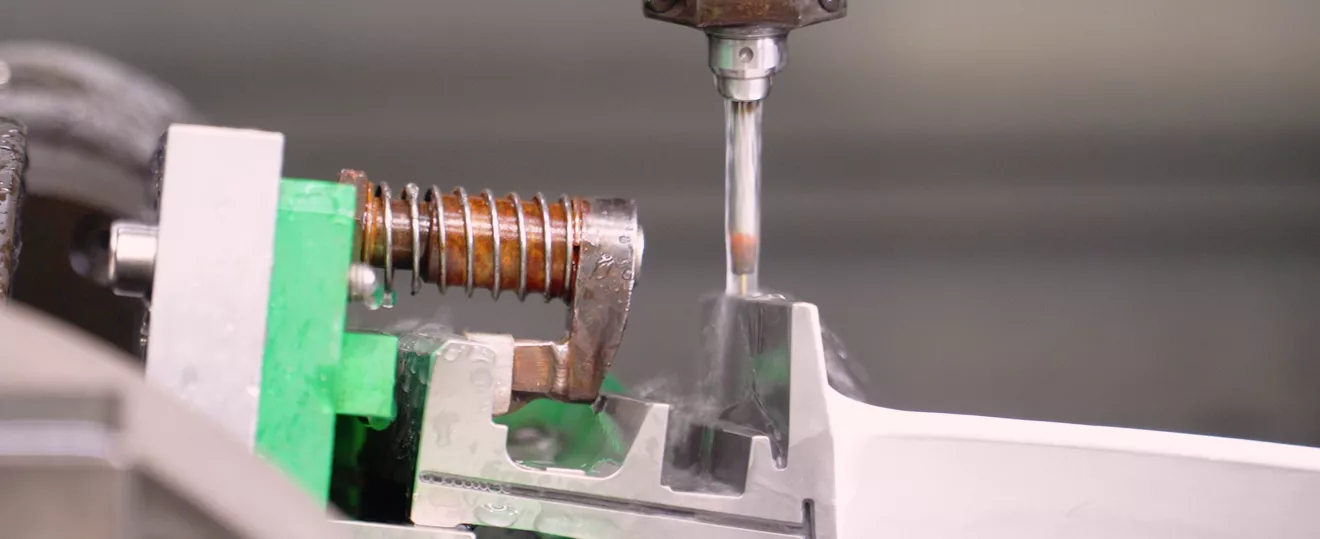

Instead of a wire, a very thin electrode—shaped to match the desired hole—is used (diameters range from 0.5 mm to 5.5 mm, with depths up to 500 mm). Thousands of electrical discharges per second cause the electrode to slowly penetrate the material vertically with great accuracy, as programmed by the CNC. Just like with wire EDM, the electrode and the part never touch. Material is “vaporized” in microscopic amounts during the microdrilling process.

Would you like more information about our Wire EDM or EDM Microdrilling services?

Interested in visiting our facility and meeting the team?

Need a quote for batch production?

Write to: info@silmec.net

Tel. +39 011 969 6363